Timberwolf Firewood Processing Equipment

Pro-HD X

Pro-HD X

Firewood Processor

Machine & Price includes 4-Way Wedge.

- The Pro-HD X is Timberwolf's mid-range firewood processor. The Pro-HD X has an electric autocycle, separating it from the Pro-HD, which has a manual autocycle.

- A 56 HP Hatz engine is equipped to the Pro-HD X firewood processor. The engine powers a 3-stage Permco gear pump, which controls the processing functions of the firewood processor with a chainsaw.

- The splitter is powered by a pump flow of 22 GPM in the first stage, while the power saw is powered by the same flow rate in the second stage. The third stage, which has a pump flow of 18 GPM, handles the auxiliary functions of the Pro-HD X, including the conveyor, live deck, and feed trough. This configuration enables faster and more powerful operations from the feed trough to the power saw.

- The firewood processor has a 16' trough length but can process logs as long as 32' because of our patented top roll clamping system and hourglass-shaped back roller.

- The top roll clamping system applies 1,000 pounds of downward pressure on logs being processed, which allows the clamping system’s teeth to bite into the log and advance it forward, and eliminate the need for the saw to re-engage logs. The back roller's teeth engage logs and move them onto the feed trough. Plus, the back roller can move both forward and backward for adjustments.

- The firewood processing machine has a 70-gallon hydraulic tank complete with a filler breather. These features ensure that the hydraulic fluid stays clean and cool. As a result, the 70-gallon tank allows users to operate all day without taking breaks to let the hydraulic fluid cool down.

- The Pro-HD X can use one of two hydraulic cylinders: a 4" bore, 3" rod, 26" stroke cylinder, or a 5" bore, 3.5" rod, 26" stroke cylinder. Choosing a 4" cylinder offers a faster cycle time of 4.1 seconds, ideal for speeding up firewood production. Alternatively, the 5" cylinder takes 6.1 seconds to complete a cycle, but has more power and can split almost any wood.

- The exceptional speed of this wood processor is the result of the regeneration manifold combined with a 2:1 cylinder ratio, resulting in high cycle times and excellent splitting performance.

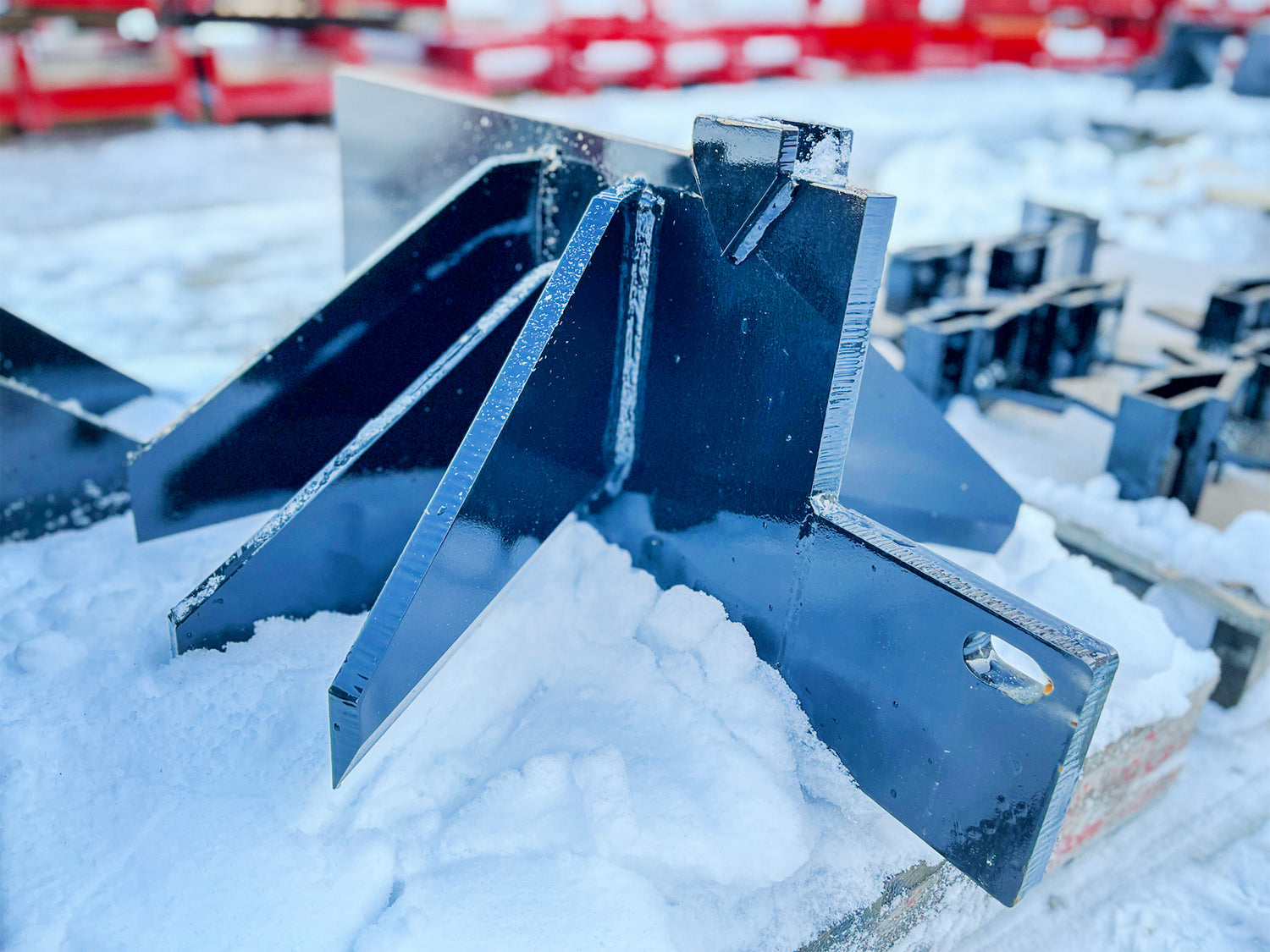

Switch Out Your Wedge and Increase Your Output

A 4-Way, 6-Way, 8-Way, or 12-Way Wedge can be equipped to your firewood processor, and each will split different quantities. For example, the 8-Way Wedge shown will output eight uniform pieces. Additionally, all of our wedges are constructed from AR400 steel, which is designed for abrasion and wear resistance.

Patented Top Roll Clamping System

Timberwolf's patented top roll clamping system distinguishes our Pro-HD series firewood processors from the competition.

The clamping system has a unique shape, allowing it to fit any sized log that will fit on the feed trough. The top roll clamping system engages logs with its teeth, giving operators full control of the log for exact cuts without having to re-engage the saw.

Shave some time off your next firewood processing project with the Pro-HD X firewood processor.

How to Process Long Logs Quickly

All Pro-HD series firewood processors feature an hourglass-shaped back roller that significantly increases the log length the firewood processor can handle, allowing the firewood machine to process logs as long as 32'.

Eliminate the need to cut your logs before processing them. Save your time, we know how valuable it is.

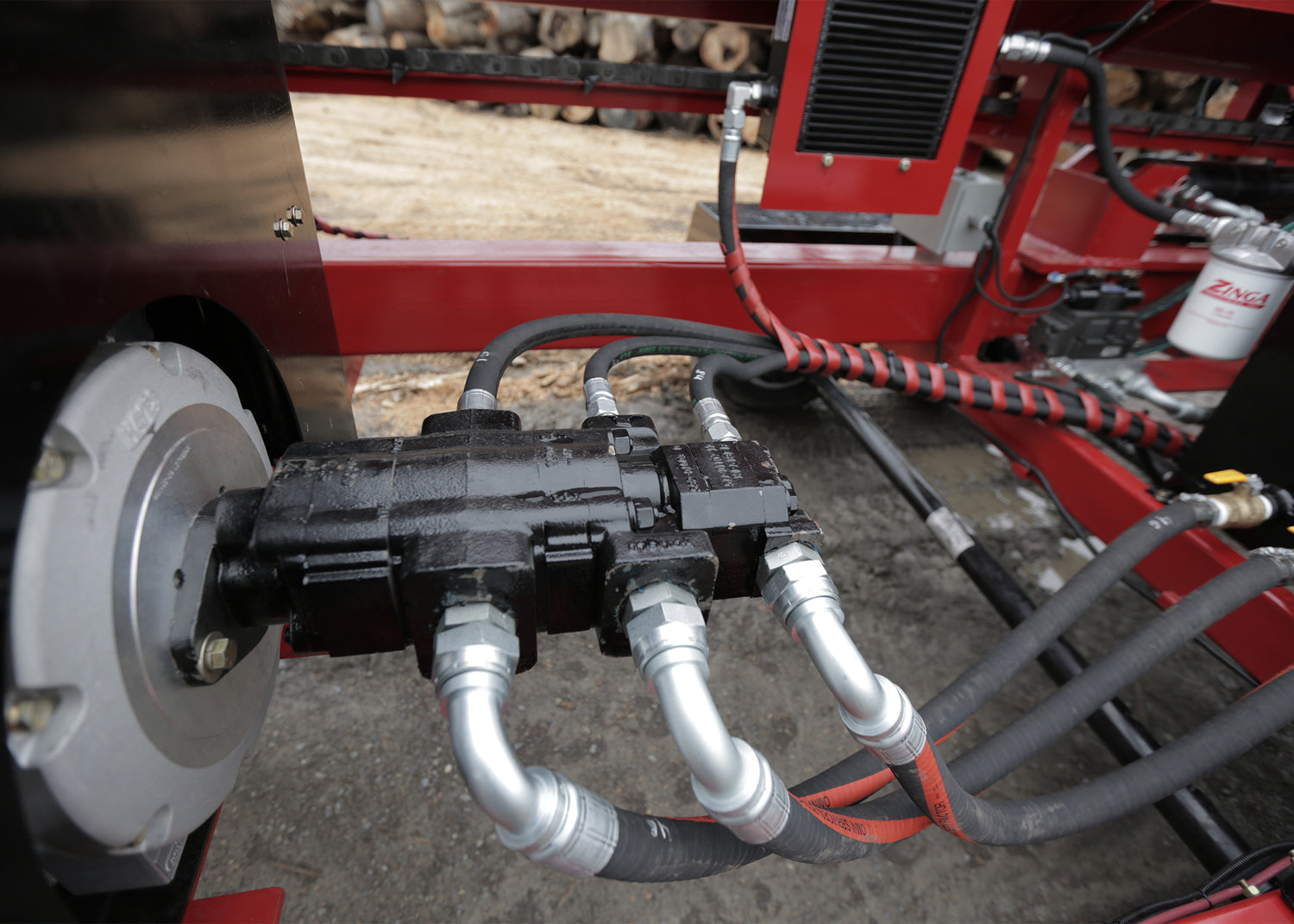

3-Stage Gear Pump

A 3-stage Permco gear pump controls various features of the wood processor with a chainsaw. The first stage has a pump flow of 22 GPM and powers the splitter. The second stage has a pump flow of 22 GPM and powers the saw. The third stage controls the auxiliary functions of the Pro-HD X processor, such as the conveyor, live deck, and feed trough, with a pump flow of 18 GPM. These flow rates allow for faster and more powerful operations, from the feed trough to the power saw.

Hydraulic Power and Speed

One of two hydraulic cylinders can be used with the Pro-HD X wood processor: a 4″ bore, 3" rod, 26″ stroke cylinder, or a 5″ bore, 3.5″ rod, 26″ stroke cylinder. The 4” cylinder offers a 4.1-second cycle time for greater firewood production, and the 5” cylinder has a 6.1-second cycle time with greater splitting force, capable of splitting any log.

This large firewood processor can operate with quick cycle times because of the regeneration manifold, combined with our 2:1 cylinder ratio. Rapid cycle times make for greater splitting quantity, but with the same Timberwolf quality.

56 HP Hatz Diesel Engine

We understand that firewood processing is a constant battle between power and speed, so we use a 56 HP Hatz diesel engine with our Pro-HD X firewood processor to provide both.

Equipped to the processor because of its long run times and consistent power, the diesel engine drives a 4.1-second cycle time when equipped with the 4" cylinder option.

Consistent and Powerful Hydraulics

A 70-gallon hydraulic tank is featured on the Pro-HD X, with internal baffles to eliminate vortices. Not only do vortices cause breaks in production, but they are also a safety risk when dealing with high-pressure hydraulic fluid.

The large hydraulic tank leaves enough room for fluids to filter and cool, so you can safely operate this firewood processor's quick and powerful functions.

Live Deck Options with a Hydraulic Lift

The Pro-HD X processor comes standard with a 3-stand live deck that is raised and lowered by a hydraulic lift, controlled by the operator with a single spool. The live deck can easily be stored vertically for transportation.

A 5-strand live deck can be added to any of our Pro-HD firewood processors. A 5-strand live deck better handles small and crooked logs.

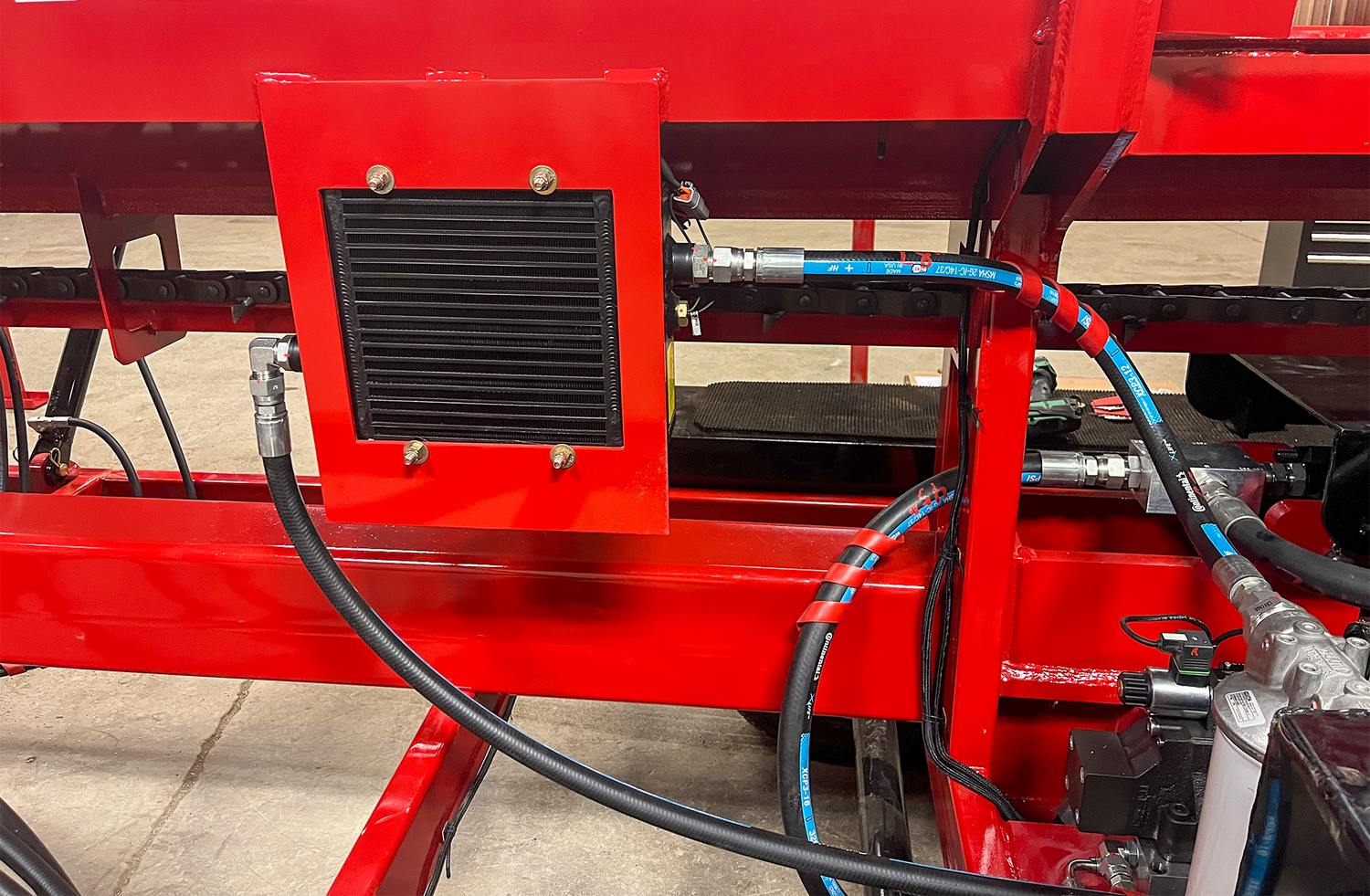

Continental Hoses

All Timberwolf firewood processing machines use Continental hoses to route the flow of hydraulic functions. We use Continental hoses because of their heavy-duty rubber construction, abrasion and kink resistance, and, most importantly, their ability to withstand high pressure fluids.

Customer safety is a top priority for us, so we use the highest quality materials to ensure your safety.

Firewood Processor Wedge Lift

With the Pro-HD X's hydraulic wedge lift operators can raise and lower the firewood processor wedge from the operator's panel. This Pro-HD X function eliminates the need for operators to manually change the wedge height or change out the wedge altogether.

Just size up your block and watch your processor wedge of choice split the log into uniformly sized firewood. Then do it all again, no matter the size of your block.