Timberwolf Firewood Processing Equipment

TWC-16

TWC-16

Wood Conveyor

Couldn't load pickup availability

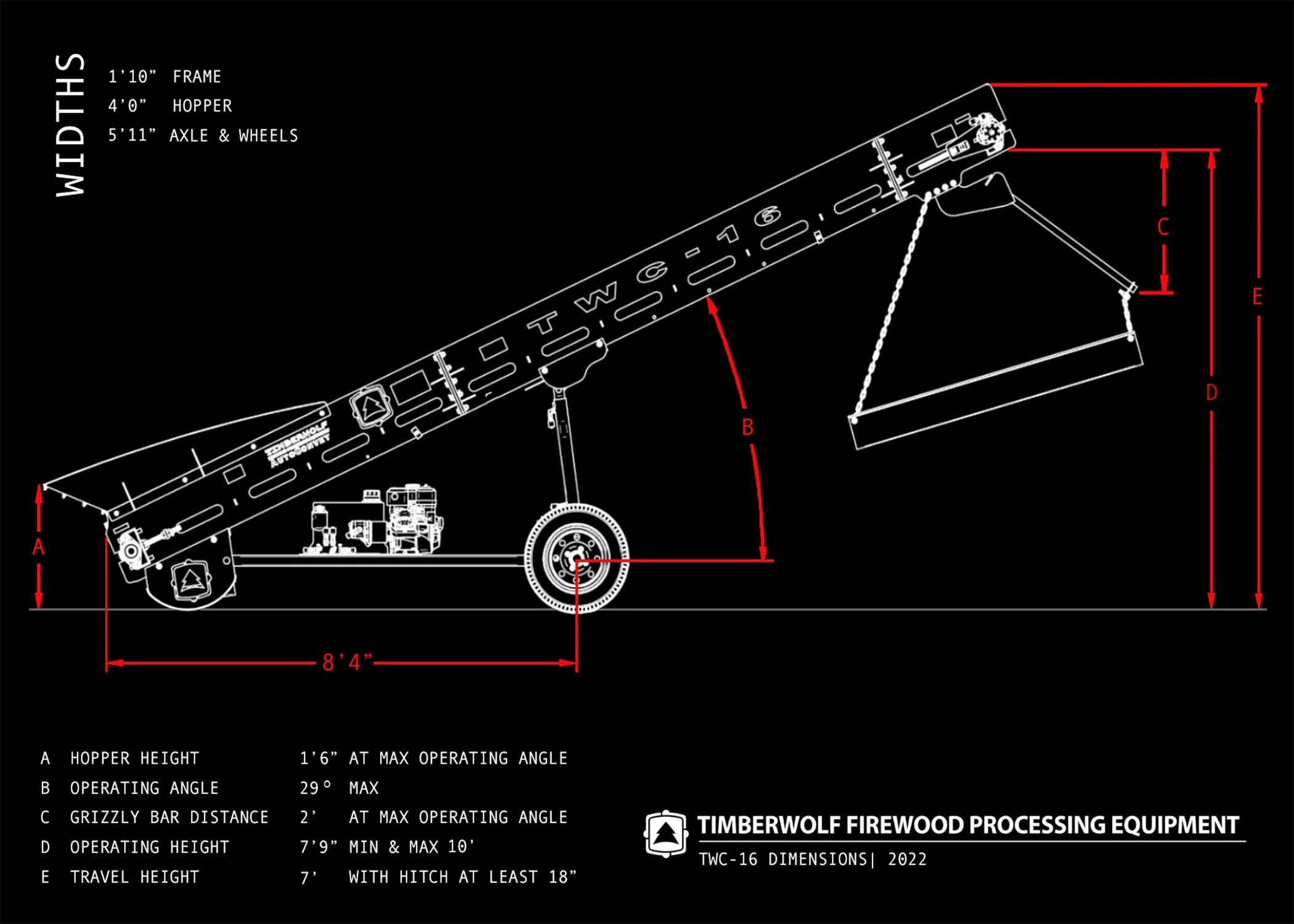

- The TWC-16 conveyor has a maximum working height of 10', a minimum working height of 7'9", and a travel height of 7'.

- At its full functioning height, the firewood conveyor can store a huge stack of seasonal firewood, and at its lowest working height, it can load the bed of a pickup truck. Then, using the same pickup, you can attach the wood conveyor with a 2" ball hitch and move on to your next project.

- Adjusting the height of the log conveyor is easy with our hydraulic lift cylinder. The lift cylinder is controlled by a single-spool valve and can be adjusted multiple times to meet the needs of each project.

- Constructed from 3/16" High Steel plate steel on the bottom and 1/8" on the sides, the hopper is rugged and bolts on for easy removal and upgrades. The TWC-16's modular hopper makes loading logs easier, as its funnel shape allows it to be filled directly with the loader's buckets.

- A ground skid is included with all TWC models. The ground skid maintains contact with the hard ground, ensuring the firewood elevator is stable when handling heavy loads. It also raises the roller off the ground, making room for falling debris.

- The fines deflector does the same for debris separation. It prevents dirt from falling into the roller. These features result in a cleaner stack of firewood at the end of the conveyor and a longer product life.

- Belt tracking is a constant problem with many conveyor belts on the market, causing production stoppages that we aim to avoid with our TWC wood elevators. Due to the design of the log conveyor's tapered rollers, if the belt is misaligned, it will retract to the center, even if the conveyor is on uneven ground.

- Optional 36" long Grizzly Bars can be added to the firewood splitter. This optional accessory attaches to the end of the conveyor and wipes out fine material from firewood before unloading. Grizzly Bars can only be installed on the TWC-16, TWC-24, and TWC-32 models manufactured after July 2017.

Self-Aligning Tapered Rollers

Belt tracking is a constant issue with many log conveyors on the market, causing breaks in production we aim to avoid with the TWC-16. Because of the wood elevator's tapered rollers design, the belt will pull itself back towards the center if misaligned, even if the conveyor is on slightly uneven ground.

Rubber Belt Fines Deflector

The rubber belt fines deflector prevents debris from falling into the log conveyor's roller. This results in a cleaner pile of firewood at the end of the conveyor belt and a longer product lifespan, so you can keep boosting your productivity for decades.

Spool Valve Controlled Height Adjustments

The TWC-16 firewood conveyor's hydraulic lift cylinder raises and lowers the conveyor, capable of operating as high as 10' in the air and as low as 7'9". The hydraulic lift cylinder is controlled by a tandem center spool valve, located on the Power Pack frame.

By simply removing the hydraulic lift cylinder's pull pin and using the tandem center spool valve, users can make quick height adjustments to the log conveyor without skipping a beat in production. Once the desired height is achieved, lock the lift cylinder into place by re-inserting the pull pin and securing it with a cotter pin.

Safely Transport Your Firewood

All Timberwolf firewood elevators come standard with a ground skid and modular hopper constructed from High Steel plate steel. The ground skid is located beneath the hopper and maintains solid contact with the ground to ensure stability, as well as lifts the firewood conveyor's roller off the ground so unwanted debris can fall through.

These overbuilt features increase the firewood machine's lifespan, as well as create a safe operator experience.

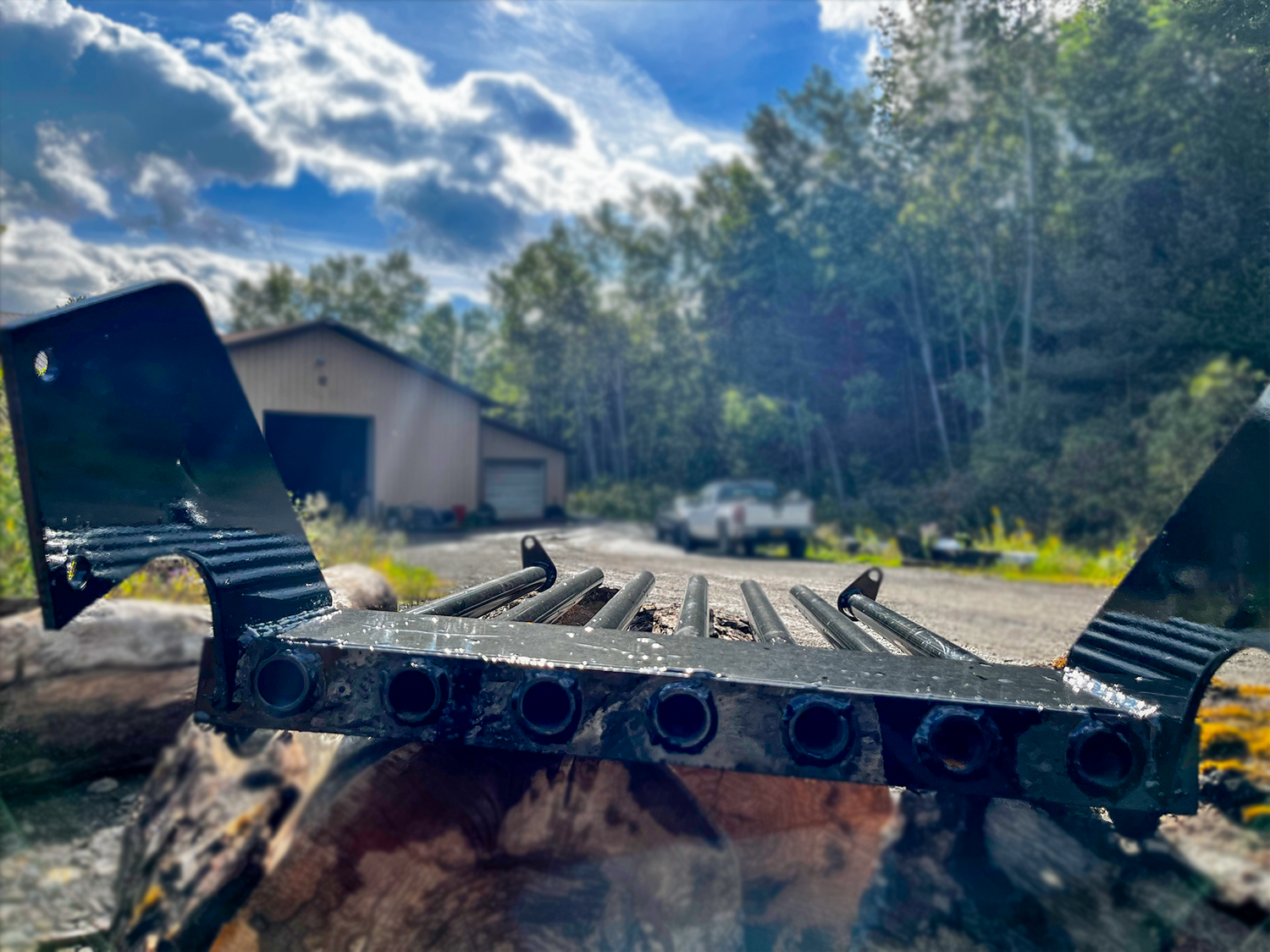

Packaged Firewood Without the Fine Material

The TWC-16 wood conveyor will sift out fine materials on its own as logs are moved, but to ensure cleanliness when offloaded, we recommend our optional Grizzly Bars.

The 36" long Grizzly Bars separate fine material from split logs as they are offloaded. With a bolt-on frame, the Grizzly Bars can easily be attached to the end of your firewood conveyor.