Timberwolf Firewood Processing Equipment

Pro-MP X

Pro-MP X

Firewood Processor

Machine includes 4-Way Wedge

- The Pro-MP X firewood processor, starting at $49,995.95, is capable of cutting and splitting logs as wide as 24" in diameter and over 32' in length.

- Sure, you may not always work with large logs, but having a reliable wood processor that can is crucial. You don't want to waste time and effort loading a log onto your small wood processor only to find out it can't handle it.

- With other manufacturers, you'd have to spend at least twice the cost of a Pro-MP X just to process logs of the same size. Compared to the Pro-MP X mobile firewood processor, which starts at $49,995.95 and can be customized with add-ons, the choice is clear.

- The secret behind the Pro-MP X’s ability to handle logs over 32' in length lies in its hourglass-shaped back roller and Timberwolf's patented driven top roll clamping system. The driven roller clamp applies 1,000 pounds of downward pressure on logs, ensuring even crooked ones can be processed smoothly. When in "float" mode, the driven roller clamp applies 300 pounds of pressure, allowing for easy adjustments and perfect cuts with the hydraulic saw.

- This 25 HP automatic wood processor comes with a 6' by 12' 3-strand live deck with a hydraulic lift as standard. The live deck can hold up to 2 face cords of wood and features driven roller chains that move logs onto a 16' feed trough. For transportation, the live deck can be stored vertically and secured with a stow bar.

- The Pro-MP X’s feed trough is equipped with two driven trough rollers and the aforementioned top roll clamp, making log adjustments on the feed trough a breeze.

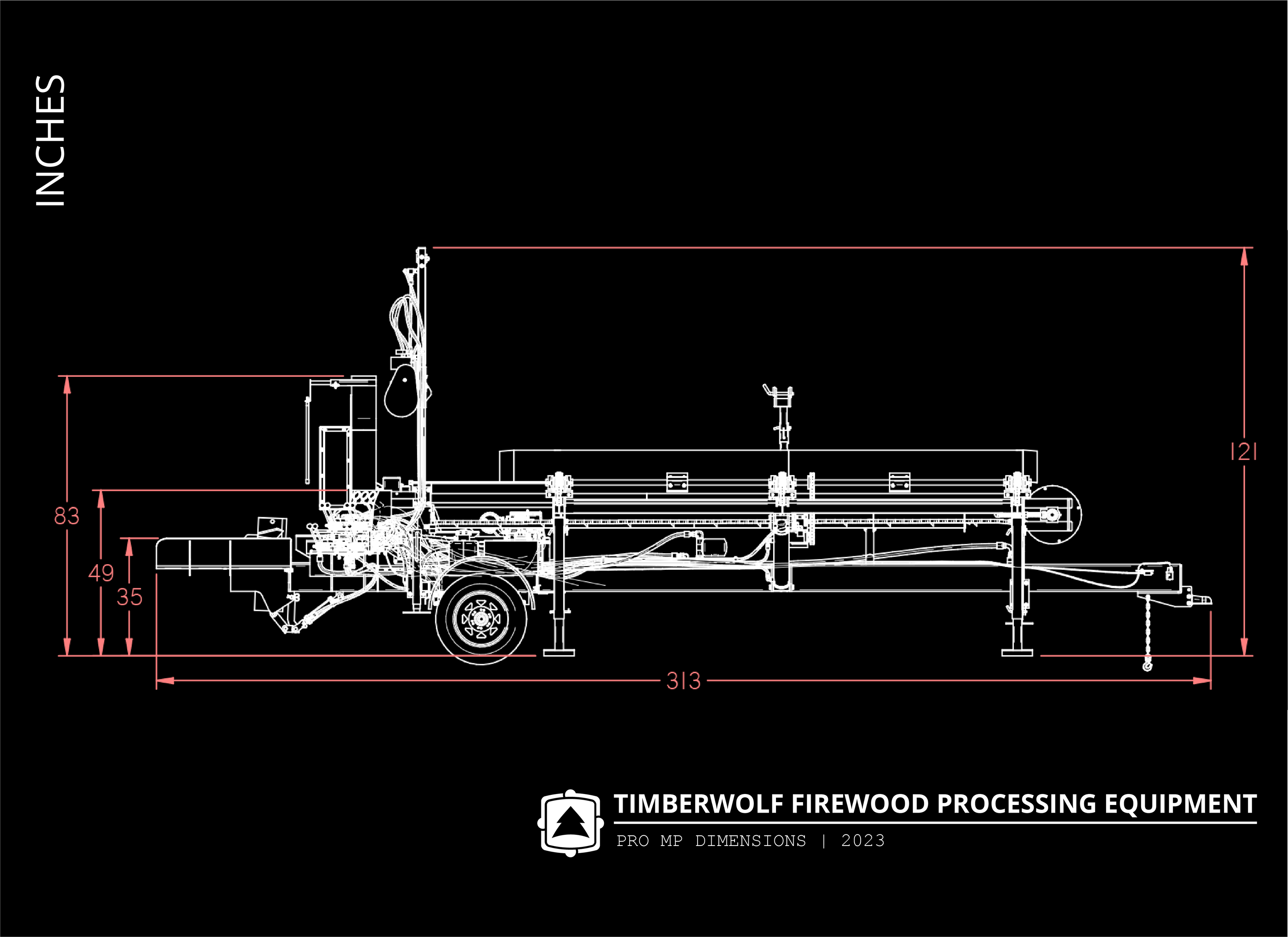

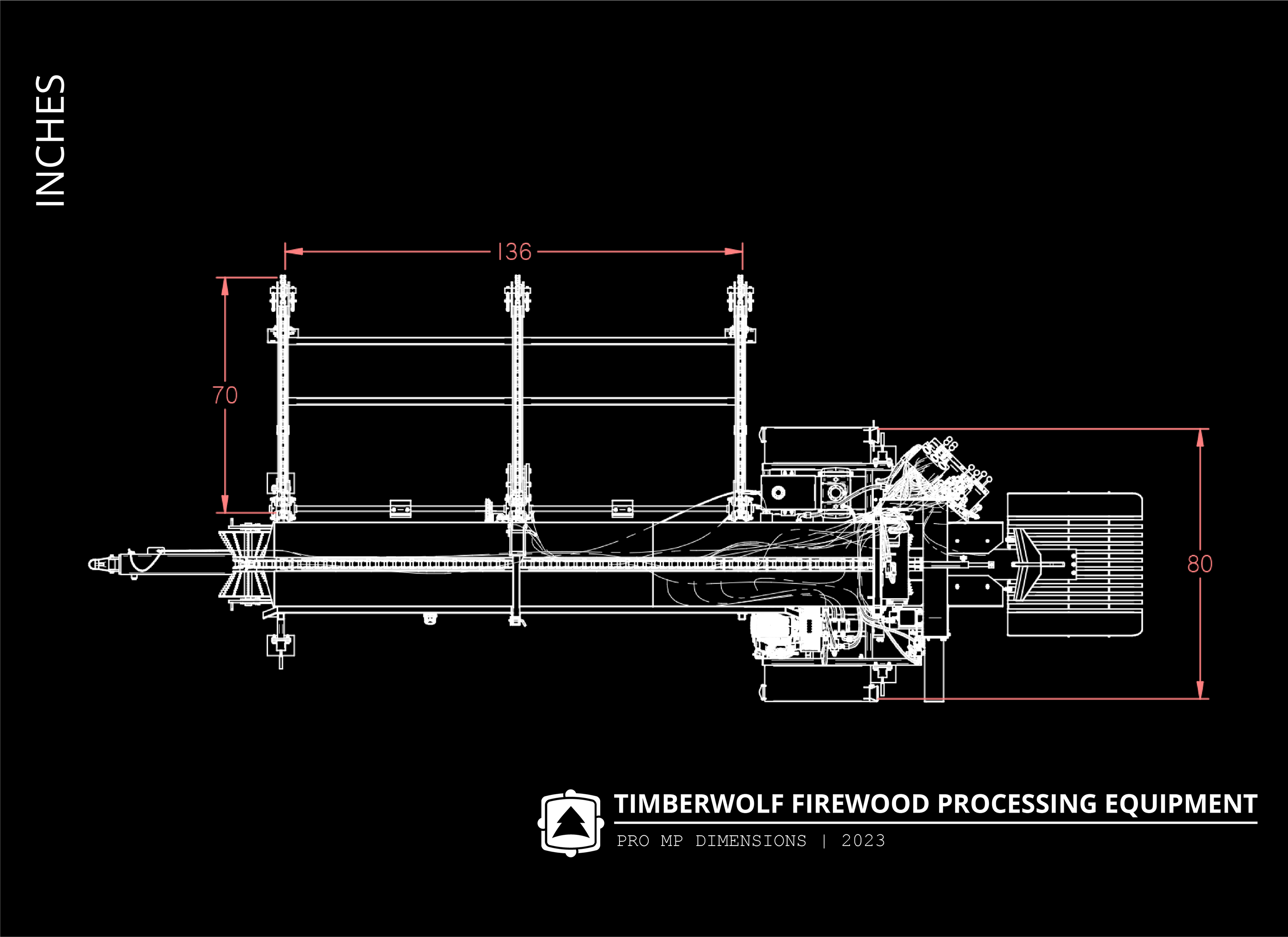

- One of the biggest challenges with firewood processors is finding the right location and setting them up. But with the Pro-MP X, that's a thing of the past. This portable processor weighs 5,500 pounds and can be easily towed by any half-ton truck. So, you can take it wherever the logs are, eliminating the need to waste miles on your logging truck. It's convenience and efficiency rolled into one.

- The Pro-MP X is powered by a GX800 Honda engine that offers 25 HP. The automatic processor’s hydraulic system, driven by a 4" or 5" cylinder, ensures a quick cycle time of just 5 or 7 seconds, depending on the cylinder size. Unlike the standard Pro-MP, the Pro-MP X has an autocycle so you can bust blocks with the push of a button. This allows the Pro-MP X to output 2.5 cords per hour.

- The automatic firewood processor's push block cylinder receives a pump flow of 22 GPM, 18 GPM flows to the saw and wedge lift, and 2.6 GPM to the auxiliary functions, like the top roll clamp cylinder.

- With a large 30-gallon hydraulic tank, the Pro-MP X operates with cool and filtered hydraulic fluid throughout the course of your operation, so you don’t have to stop production to let your fluid cool.

- This mobile wood processor comes standard with a 4-Way Wedge, perfect for boiler wood, but a 6-Way Wedge can be added on for making premium firewood. The hydraulic wedge lift, combined with the mid-sized processor's design, allows for easy access to the splitting chamber for re-splits. So, whether you need to split logs into four or six pieces, the Pro-MP X has got you covered.

Easily Handle 24" Diameter Logs

With competitors, it will cost you upwards of $80,000 just for a wood processor that can process a 24” wide log - and just because these machines can, it doesn’t mean they should.

The Pro-MP X automatic wood processor has a frame more than capable of processing large logs. Also, the frame of the mid-sized log processor is designed for accessibility, making adjustments not only easy but safe.

Turn a Tree Into Firewood

With the Pro-MP X firewood processor's back roller, it's now possible to handle 32-foot-long logs. An hourglass-shaped roller with large teeth is located at the end of the machine, enhancing the traction of forward-moving logs. This feature reduces operator intervention and results in easy firewood processing.

Hydraulic 3-Strand Live Deck

The Pro-MP X has a 6' long by 12' wide 3-stand live deck with a full roller chain, idler, and driven sprockets, so it can guide monster logs onto the 16’ long feed trough with ease. Approximately 2 face cords can rest on the live deck of the mid-sized firewood processor.

The live deck can be raised and lowered using a hydraulic lift cylinder, as well as stored for transportation using the stow bar.

Patented Top Roll Clamping System

Standard on all Timberwolf firewood processors, the driven top roll clamp is featured on the Pro-MP X. The driven top roll clamping system applies 1,000 pounds of downward pressure on forward-moving logs, which secures the logs and reduces the need for the saw to re-engage the log after the initial contact.

An hourglass-shaped roller with large teeth is located at the end of the machine, enhancing the traction of forward-moving logs. This feature reduces operator intervention and results in easy firewood processing.

Cut While You Split

Because of the multiple pumps on the Pro-MP X, operators can feed and cut a log while driving the push block to split cut logs.

22 GPM flows to the push block cylinder, 18 GPM flows to the saw and wedge lift, and 2.6 GPM flows to the auxiliary functions of the mid-sized wood processor.

Healthy Hydraulics for Years to Come

Hydraulic fluid drives powerful splitting forces, but it can also cause breaks in production when overheated, and disrupt splitting when not filtered properly.

The Pro-MP X automatic firewood processor has an oversized 30-gallon thermodynamically efficient hydraulic tank that ensures cool operating conditions, therefore extending the life of the mobile processor's hydraulic components.

The Ultimate Mobile Firewood Processor

Transporting the Pro-MP X is simple, as it has small dimensions and a weight of only 5,500 pounds. Any half-ton truck can move the towable firewood processor from one spot to another, or even miles down the road.

Easy Wedge Adjustments

With the Pro-MP X firewood processor's hydraulic wedge lift operators can raise and lower their 4 or 6-Way Wedge from the operator's panel. This function eliminates the need for operators to manually change the wedge height or change out the wedge altogether.

Plus, operators can move the wedge out of the way when reaching into the splitting chamber in order to handle logs.

Heavy-Duty Hoses

All Timberwolf firewood machines use Continental hoses to route the flow of hydraulic functions. We use Continental hoses because of their heavy-duty rubber construction, abrasion and kink resistance, and, most importantly, their ability to withstand high-pressure fluids.

Customer safety is a top priority for us, so we use the highest quality materials to ensure your safety.