Timberwolf Firewood Processing Equipment

Pro-HD

Pro-HD

Firewood Processor

Machine & Price includes 4-Way Wedge.

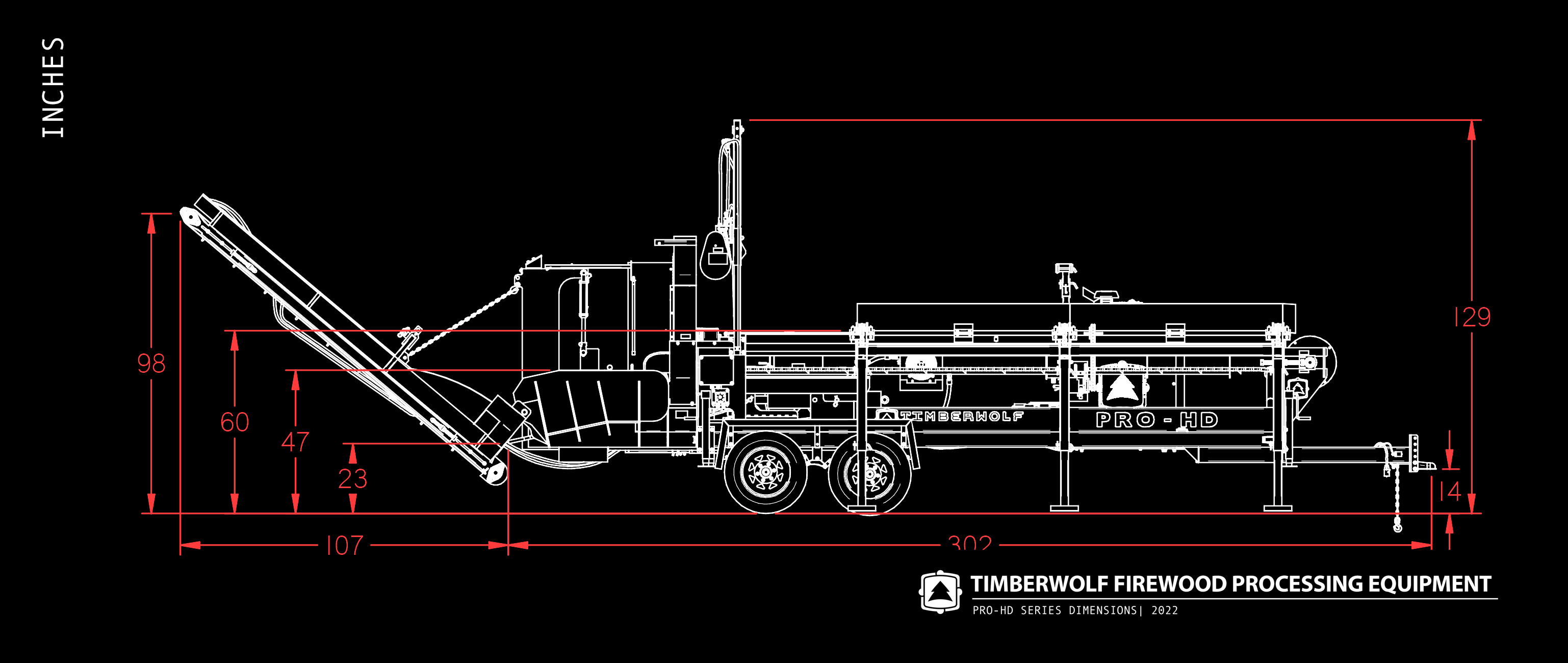

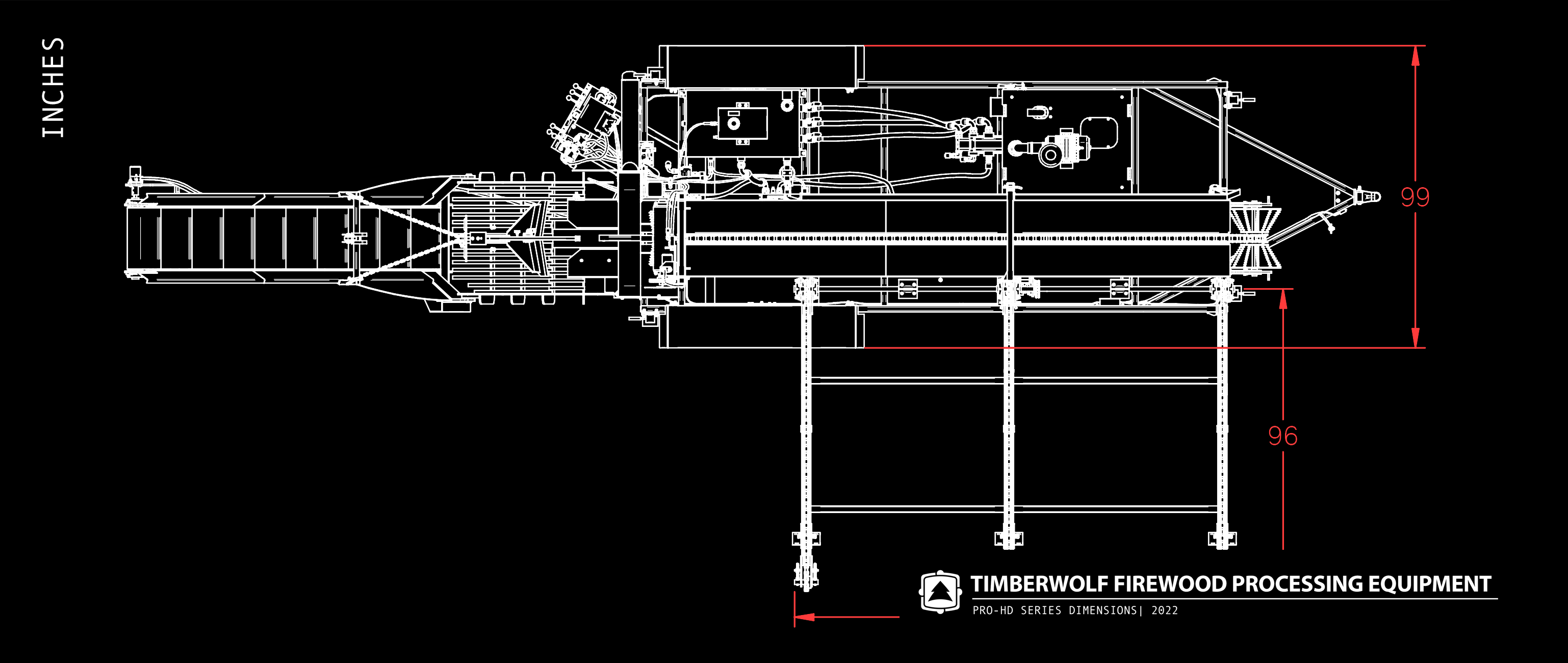

- The Pro-HD is a commercial-grade wood processor that will easily handle 24” diameter logs. The driven top roll clamp can apply 1,000 pounds of downward pressure on forward-moving logs to center them in the feed trough and reduce the need for the 25” cut/.404 chain power saw to reengage. Still, the driven top roll clamp will secure smaller logs as well, so you can process logs all day without worrying about whether your firewood processor will handle certain logs.

- The commercial firewood processor can handle logs over 32’ in length with a 16’ trough length. The aforementioned driven top roll clamping system in combination with an hourglass-shaped back roller allows for the Pro-HD firewood machine to not only handle long logs but secure them, as well as cut and split them.

- The Pro-HD log processor is equipped with a 3-strand live deck that measures 8’ in length and is 12’ wide. This live deck is designed with a full roller chain, complete with an idler and driven sprockets. So, it can easily guide even the heaviest logs onto the feed trough. With this feature, you can process an impressive 3 full cords of wood in just one hour, all by yourself. When it's time to transport the mobile processor, you can conveniently raise and store the live deck vertically using the hydraulic live deck lift and stow bar.

- The commercial wood processor is powered by a 56 HP Hatz engine. It's the 3-stage Permco gear pump that controls the different functions of the wood processor. The first stage of the pump powers the splitter, delivering a flow of 22 GPM, while the second stage powers the saw, also delivering 22 GPM. The third stage takes care of additional functions like the conveyor, live deck, and feed trough, with a pump flow of 18 GPM.

- The heavy-duty Pro-HD firewood processor can be equipped with a 4” or 5” cylinder, the 4” cylinder offering a 5.9-second cycle time and the 5” cylinder offering more splitting force. The speed and power of the commercial wood processor’s push block cylinder are the result of the regeneration manifold used on the firewood processing machine, which drives a regenerative cycle, resulting in a more rapid extension of the rod while using the same pump flow. Because of this innovative hydraulic performance, the Pro-HD can output more than 3 cords per hour, depending on the skill of the operator.

- A 4-Way, 6-Way, 8-Way, or 12-Way Wedge can be equipped with the Pro-HD log processor. All of Timberwolf’s firewood splitting wedges are constructed from abrasion-resistant steel with a 1” thick centerpiece, measuring 21” wide.

Patented Driven Top Roll Clamping System

Re-engaging your saw wastes time. Running the feed trough back and forth, trying to line up your log, wastes time.

We don't like wasting time, so we engineered, designed, fabricated, manufactured, and patented our driven top roll clamping system for firewood processors.

The driven top roll clamping system applies 1,000 pounds of downward pressure on logs being processed, which eliminates the need for the saw to re-engage when cutting logs. It also eliminates the need for operators to re-handle blocks, as the top roll clamping system ensures that cut logs will center themselves in the splitting chamber.

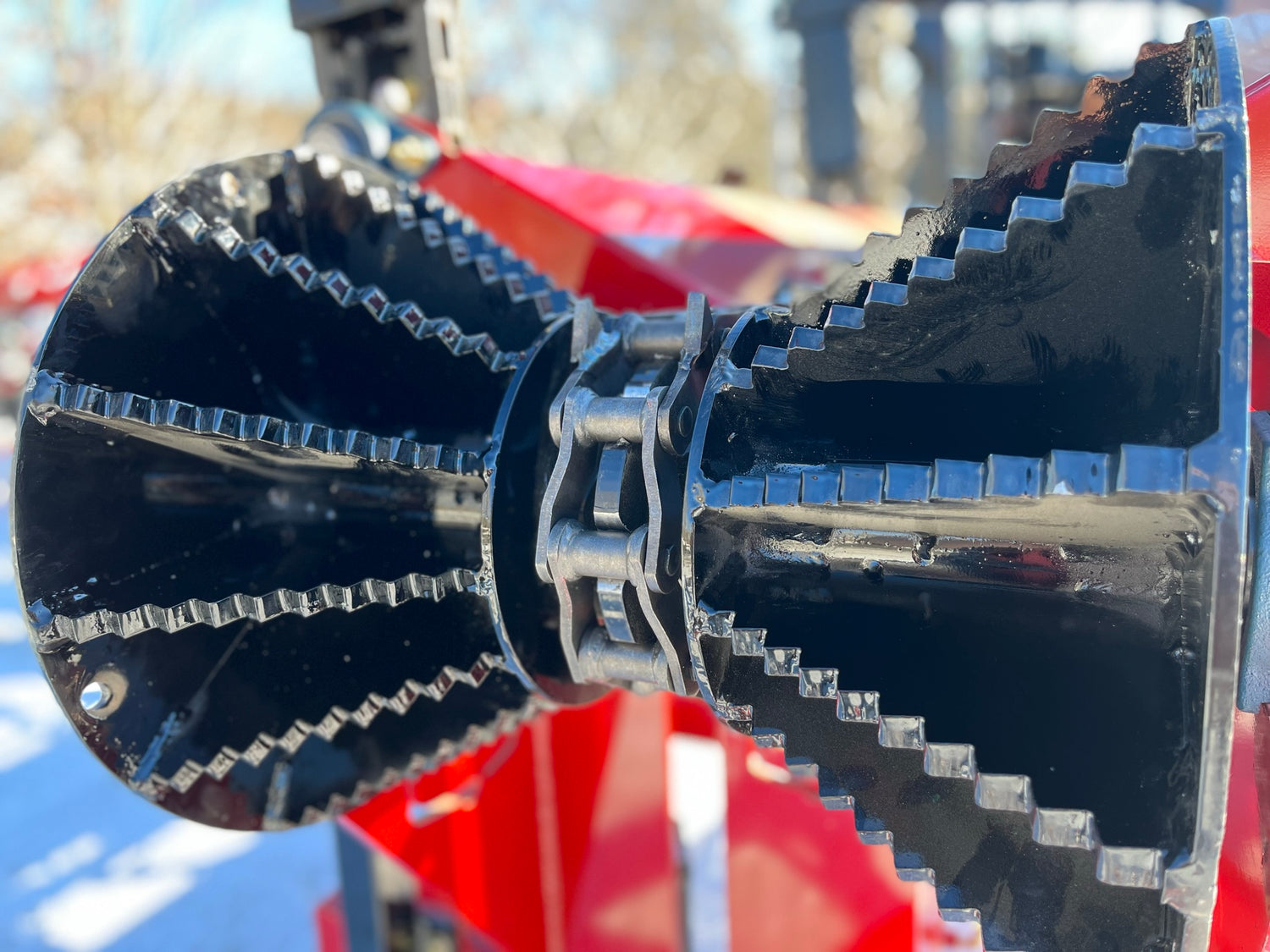

Back Roller for Longer Log Processing

The Pro-HD wood processor's back roller allows for significantly longer log processing, capable of handling 32’ long logs. This large-toothed, hourglass-shaped roller is at the end of the processor, positioned to enhance the traction of forward-moving logs. This means minimal operator interference and higher quality processed firewood.

3-Strand Live Deck with Hydraulic Lift

The Pro-HD firewood processor comes standard with a 3-strand live deck that is 8’ long. The live deck includes a full roller chain with an idler and driven sprockets, so it can guide the heaviest of logs onto the feed trough. This feature allows for a single person to process 3 full cords of wood in one hour. The live deck can be stored vertically for transportation.

56 HP Hatz Diesel Engine

The Pro-HD is powered by a 56 HP Hatz diesel engine. Equipped to the processor because of its long run times and consistent power, the diesel engine drives a 5.9-second cycle time when equipped with the 4" cylinder option.

Such quick cycle times can be generated because of the regeneration manifold used on the firewood processing machine, which drives a regenerative cycle, resulting in a more rapid extension of the rod while using the same pump flow.

Cool and Filtered Hydraulic Fluid

Hydraulic fluid drives powerful splitting forces, but it can also cause breaks in production when overheated, and disrupt splitting when not filtered properly.

The Pro-HD has an oversized, 70-gallon hydraulic tank that leaves plenty of room for fluid to cool and filter, which means no breaks in production, and ultimately, more profit.

Feed, Cut, Split, and Sell

A 3-stage Permco gear pump controls various features of the firewood processor with a chainsaw. The first stage has a pump flow of 22 GPM and powers the splitter. The second stage has a pump flow of 22 GPM and powers the saw. The third stage controls the auxiliary functions of the Pro-HD wood processor, such as the conveyor, live deck, and feed trough, with a pump flow of 18 GPM.

The advantage of a 3-stage gear pump? Operators can control various functions at the same time. For instance, an operator can drive the push block while cutting a log on the feed trough.

Stop waiting on your equipment and boost your cord output with a Pro-HD firewood processor.

Heavy-Duty Hoses

All Timberwolf firewood machines use Continental hoses to route the flow of hydraulic functions. We use Continental hoses because of their heavy-duty rubber construction, abrasion and kink resistance, and, most importantly, their ability to withstand high-pressure fluids.

Customer safety is a top priority for us, so we use the highest quality materials to ensure your safety.

Easy Wedge Adjustments

With the Pro-HD firewood processor's hydraulic wedge lift, operators can raise and lower the processor wedge from the operator's panel. This function eliminates the need for operators to manually change the wedge height or change out the wedge altogether.

Just size up your block and watch your wedge of choice split the log into uniformly sized firewood.

Wedge Options for Every Operation

Choose a 4-Way, 6-Way, 8-Way, or 12-Way Wedge to equip to your firewood processor. All of our wedges measure 21" wide with a 1" thick centerpiece that will split the gnarliest logs. Split logs cleanly and quickly with any of our firewood processor wedge options.

A 4-Way Wedge is shown here.