Timberwolf Firewood Processing Equipment

TWC-12

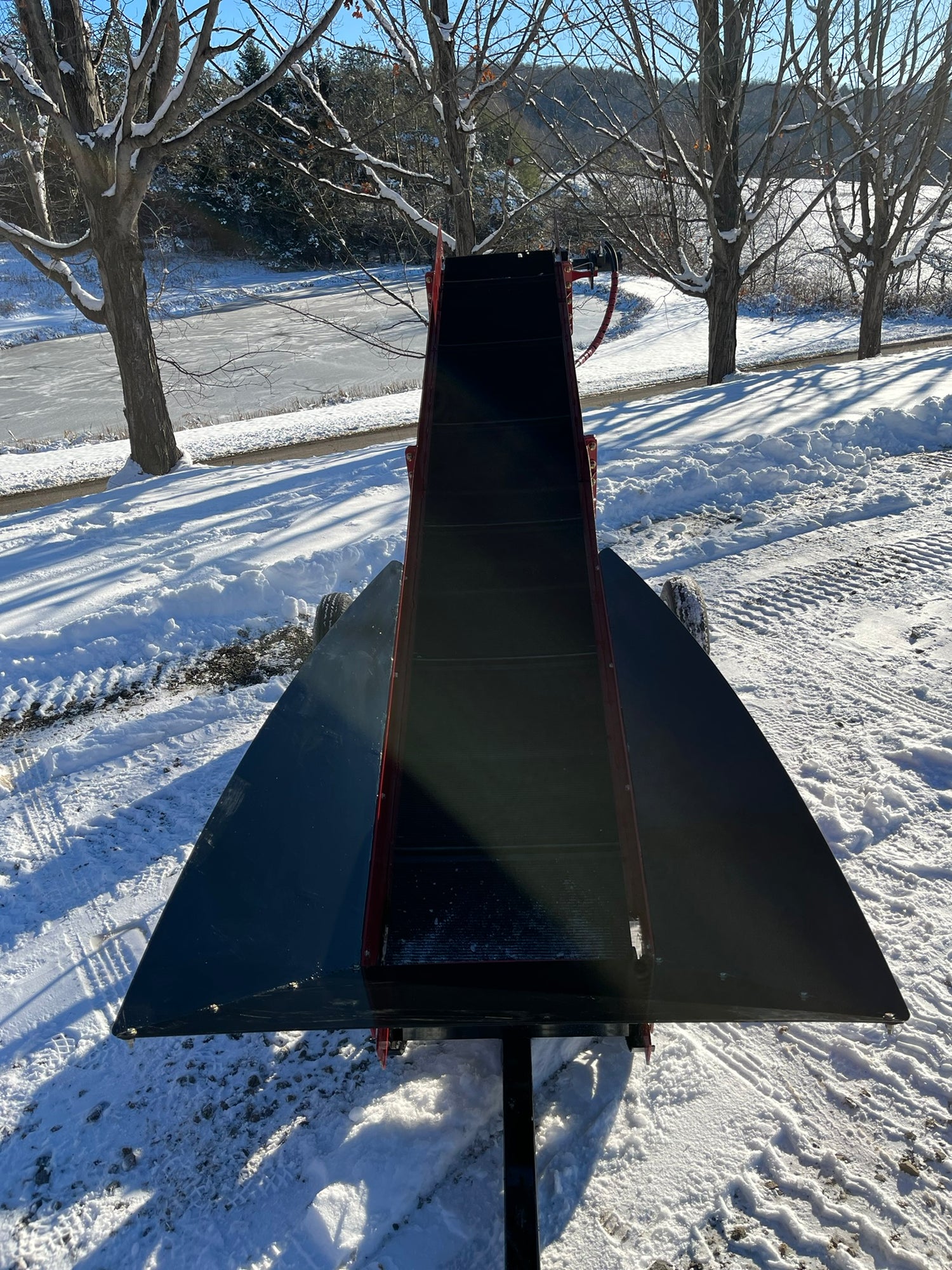

TWC-12

Wood Conveyor

Submit a quote for pricing information.

Couldn't load pickup availability

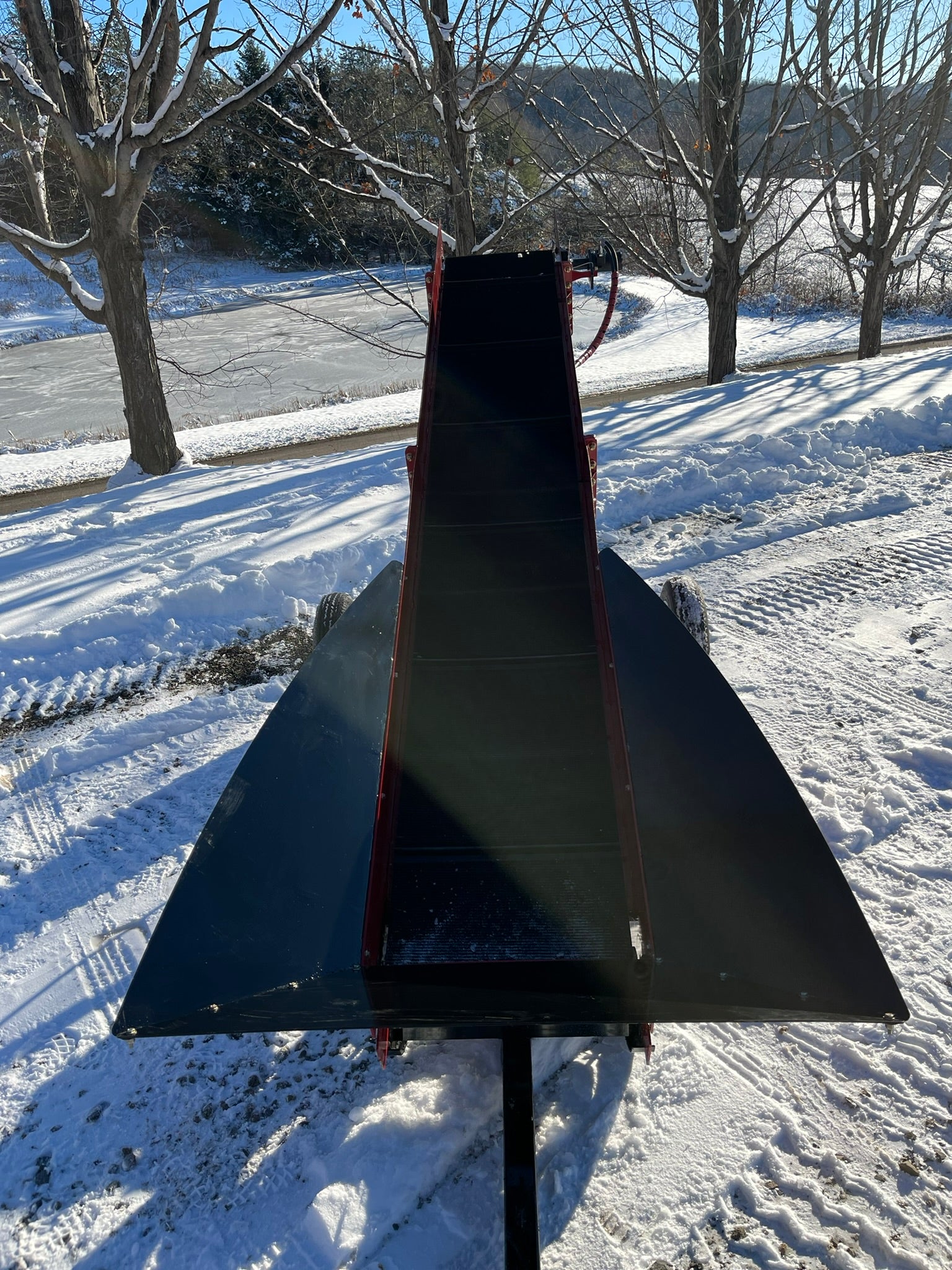

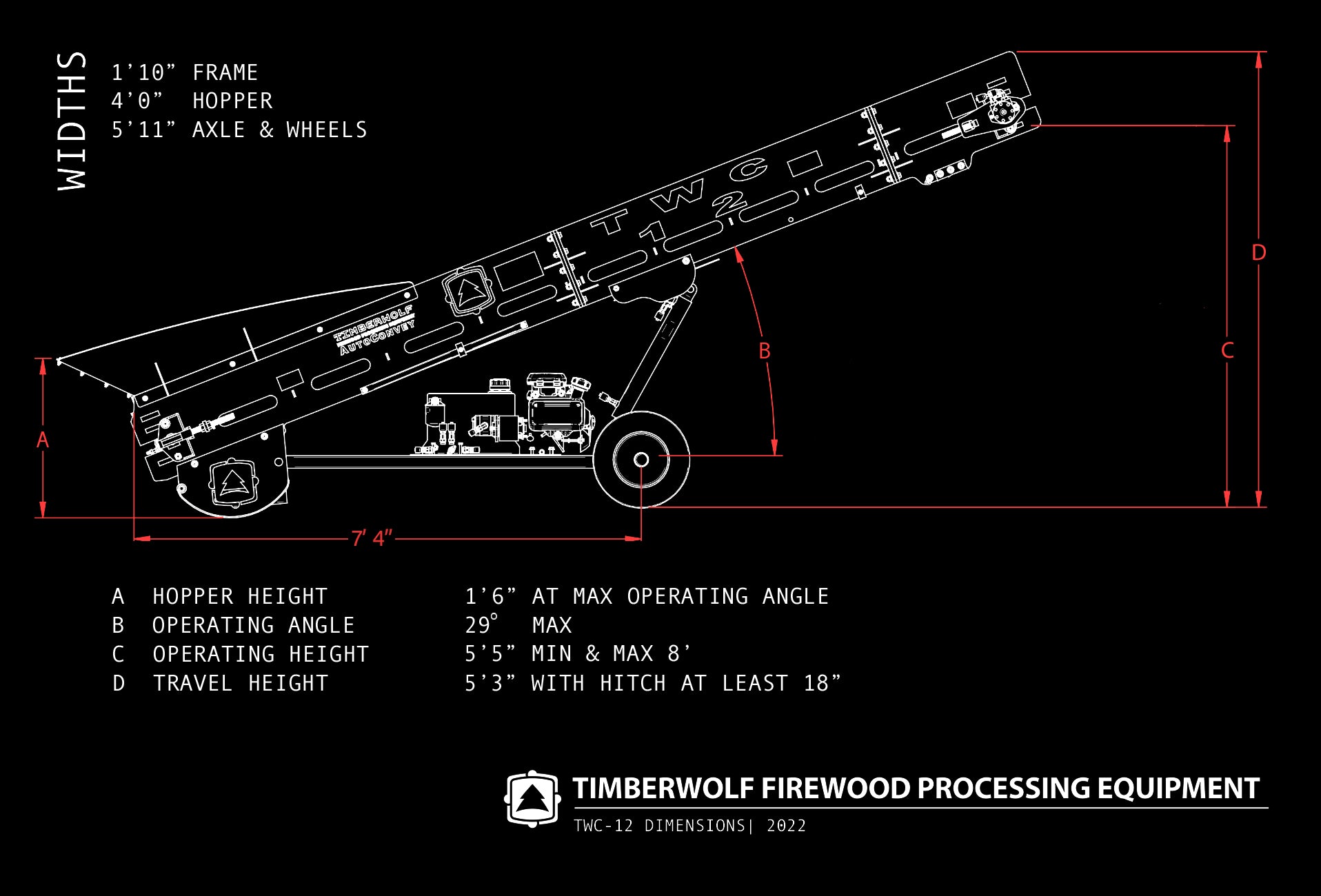

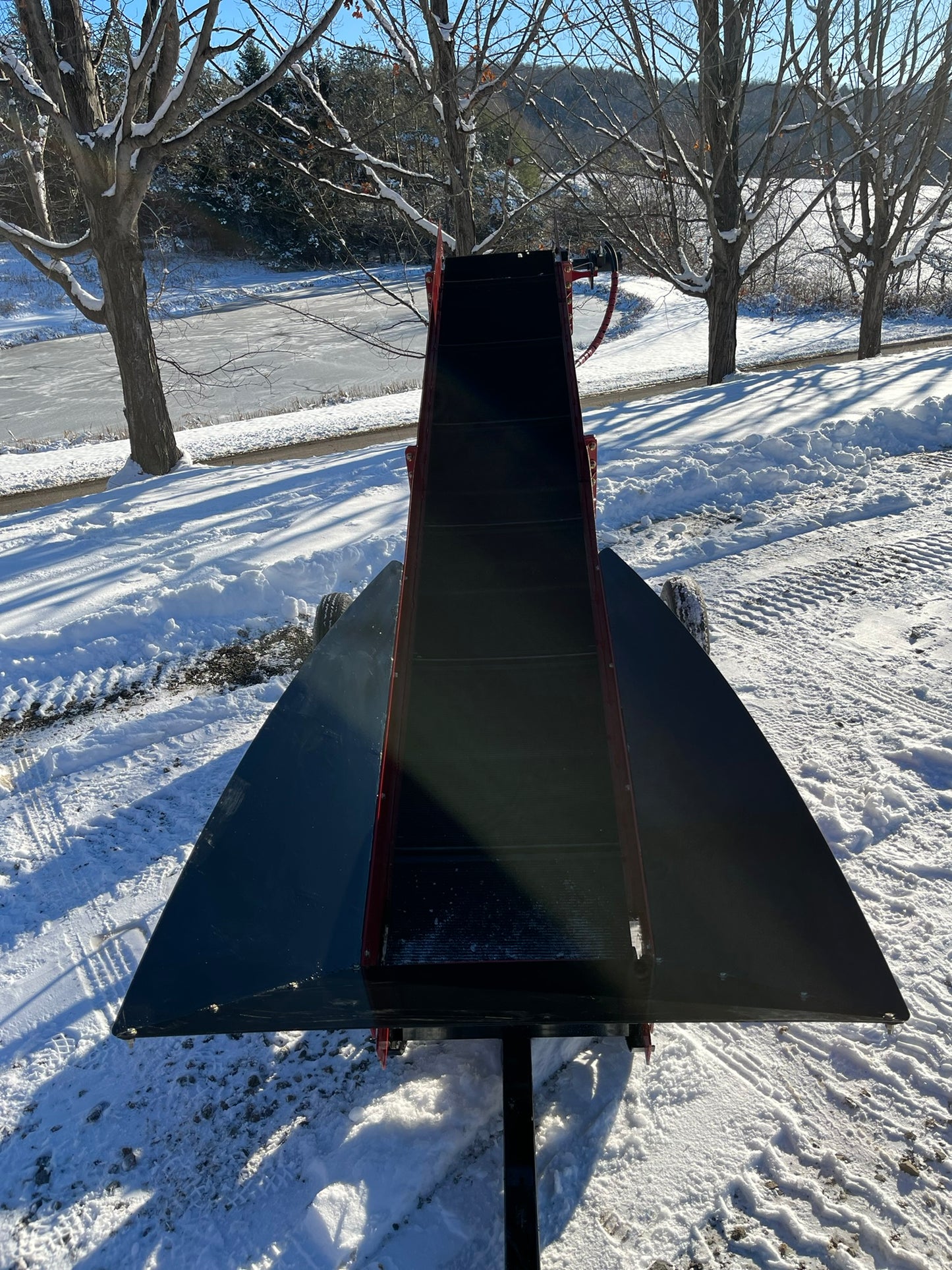

- The TWC-12 is our smallest wood conveyor, with a 12’ long frame capable of operating as high as 8’ in the air and as low as 5’5”.

- The firewood conveyor runs on a 4.9 HP Honda engine that is fuel efficient and exceptionally quiet, so you can run the conveyor anywhere, from the woods to the neighborhood.

- Adjusting the height of the TWC-12 is simple with our hydraulic lift cylinder. Coupled with a tandem center spool valve, the hydraulic lift cylinder is controlled by the operator and can be adjusted numerous times to fit the needs of any project.

- The log conveyor can be moved easily, as it has a travel height of 5’3” and a 2” ball hitch coupler for transportation. Perfect for larger operations with lots of space between projects.

- The TWC-12 wood conveyor weighs 1,055 pounds, which, along with the ground skid, provides maximum stability for this model. The ground skid maintains contact with solid ground, which keeps the firewood conveyor sturdy while handling large loads. It also lifts the roller off the ground, which provides room for debris to fall.

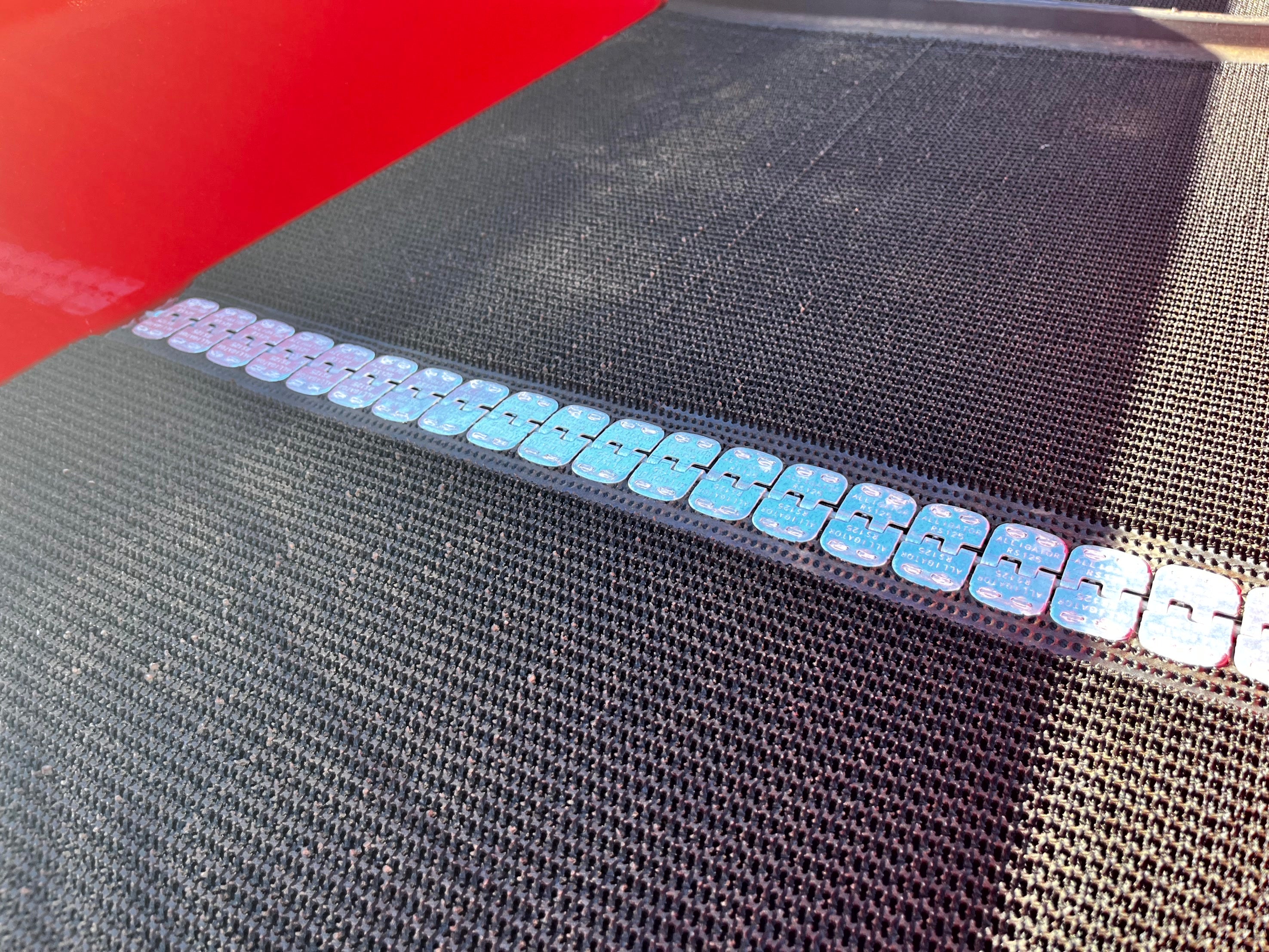

- The rubber belt fines deflector does much of the same with separating debris. It prevents debris from falling into the roller. These features result in a cleaner pile of offloaded firewood.

- The modular hopper on the wood elevator makes loading logs simple, as it can be filled directly with loader buckets because of its funnel-like shape. Constructed out of 3/16” High Steel plate steel on the bottom and 1/8” plate steel on the sides, the hopper is not only heavy-duty but also bolt-on, making removal and upgrades easy.

- Belt tracking is a constant issue with many conveyors on the market. Because of the TWC-12 wood conveyor’s tapered roller design, the belt will pull itself back towards the center if misaligned, even if the conveyor is on uneven ground.

Simple Height Adjustments

Adjusting the height and angle of the TWC-12 firewood elevator is simple with our hydraulic lift cylinder. Coupled with a tandem center spool valve, the lift cylinder is controlled by the operator and can be adjusted numerous times to fit the needs of any project. With this wood conveyor, you can load a pickup and dump truck, one after the other, without missing a beat.

Modular Hopper

The modular hopper on the TWC-12 log conveyor makes loading logs simple, as it can be filled directly with loader buckets because of its funnel-like shape. Constructed out of High Steel plate steel, the hopper is not only heavy-duty, but it is bolt-on, making removal and upgrades easy.

No More Stopping to Align Your Belt Tracking

All Timberwolf firewood conveyors come standard with tapered rollers. The drive roller and idler roller are slightly tapered inward, so the belt will self-align if it moves off-center.

This means no more breaks in production to realign your conveyor system. Just watch the offloading conveyor dump perfectly split logs into the bed of your truck.

Rubber Belt Fines Deflector

A simple but important feature, the rubber belt fines deflector prevents unwanted debris from falling into the roller. Debris falling into the roller will create an unclean pile when offloaded and may cause damage to the conveyor belt over time.

All Timberwolf wood elevators come standard with a rubber belt fines deflector.

Secure and Safe Operation

The ground skid is located at the bottom of the firewood conveyor, below the belt tensioner. The ground skid maintains solid contact with the ground at all times, so the conveyor can stay sturdy and avoid tipping during operation.

The ground skid also lifts the roller off the ground, which provides more room for debris to fall. That means a clean pile of offloaded firewood and an increased product lifespan.